The Macomb Group Hose Division offers quality hose assemblies, providing solutions in many industries, including petroleum, power generation, mechanical, chemical, pharmaceutical, agricultural, food and dairy, and more. The team supplies their customers with hose needs from 1/8 of an inch to 14 inches in diameter — and everything in between. No matter the job, they can create custom solutions using materials from industrial rubber and thermoplastics to polypropylene, stainless steel, and others. With so many options for nearly any project specifications, how does the Hose Division do it?

“We’re problem-solvers,” said Macomb Group Hose Division Manager Tim Chapman. “Customers tell us their needs and what they’re looking for; we ask the right questions to figure out what will work best for them.”

This sentiment is characteristic of the entire Macomb Group, and the Hose Division is no exception. With their knowledge, experience, and attention to detail, the Hose Division team can do it all to the highest industry standards right from Livonia.

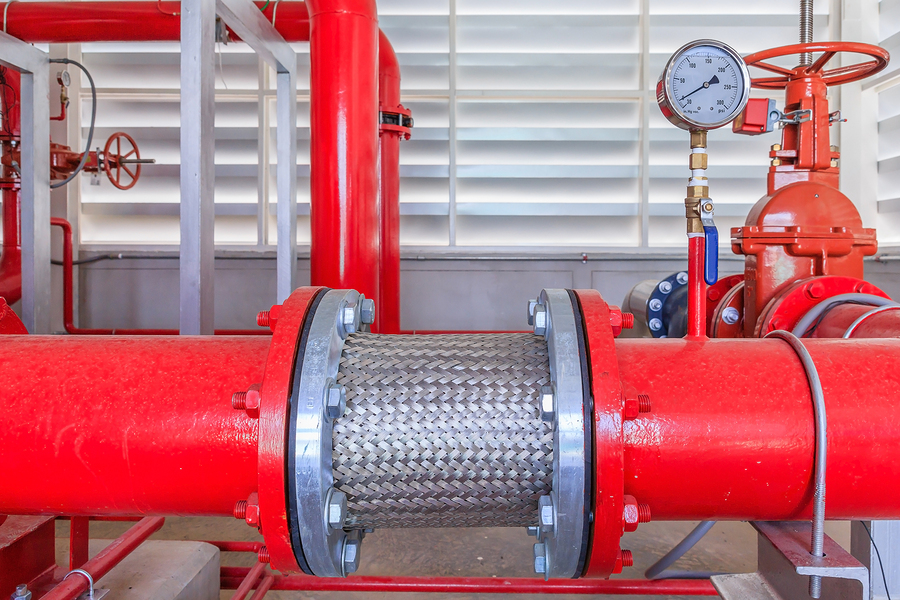

“We quote and assemble all different types of hose assemblies,” Chapman said. “We also sell bulk hose — air, chemical, water, and Teflon-lined pipe for customers — and we make metal hoses. We have two welders on site to fabricate those hoses.”

Hose Division leader Chapman and his crew work hard to provide a huge variety of specialty fabricated hose solutions for their customers’ fluid, steam, and air-handling systems across the country. With more than 20 years’ combined experience, they’re able to engineer custom hoses and deliver the safest and most cost-effective flexible piping and hose solutions for any client’s requirements.

Hose Division leader Chapman and his crew work hard to provide a huge variety of specialty fabricated hose solutions for their customers’ fluid, steam, and air-handling systems across the country. With more than 20 years’ combined experience, they’re able to engineer custom hoses and deliver the safest and most cost-effective flexible piping and hose solutions for any client’s requirements.

Today, the team is gearing up for a three-year project to provide all the welded metal hoses for a large joint-venture project in Ohio while continuing to supply their current customers. Despite the influx of business, Chapman is proud of the group’s attention to detail and ability to consistently provide the best service.

“We have the knowledge and experience to know what works and help customers through any project,” he added.Chapman also recognizes the hard work the division puts in and the tight-knit group they’ve become.

“We have a great team here: Jen, Leo, and Pat — those three are the best, and they make this thing work,” he said. “We ask the necessary questions to get all the information upfront to avoid any type of problem.”

As we all well know, time is of the essence for any project — big or small. Chapman and his colleagues in the Hose Division work closely with you and your team to make sure you get all the necessary components when you need them to make your projects as seamless as possible. No matter what your hose needs entail, the Hose Division is here to help you find a solution and supply you with the best products to get the job done safely, securely, and within budget.