Tags: Baum, Lined Pipe, Lined Pipe Fabrication, Polypropylene, PTFE (polytetrafluoroethylene), PVDF (polyvinylidene fluoride)

Chemical Companies, Power Plants, Steel facilities, Mechanical Contractors, and others requiring lined pipe for their critical application projects have a new resource to turn to – the new lined pipe fabrication center, located at The Macomb Group’s Midland, Michigan location.

This recent addition provides custom fabrication services for the Baum America line of plastic lined carbon and stainless-steel pipe and fittings, with services provided by a factory trained and certified technician, according to Branch Manager Scott Henegar.

“We’ve have had a long standing distribution agreement with the Baum America line of products and appreciate the company’s decades-long reputation for quality and technical experience,” Henegar notes. “It has been an ambition of Macomb to strengthen that relationship through expanded local inventories and in-house fabrication capabilities. After a period of careful evaluation and discussion between both parties the decision was made late last year to proceed and we can now confidently offer that inventory and service”.

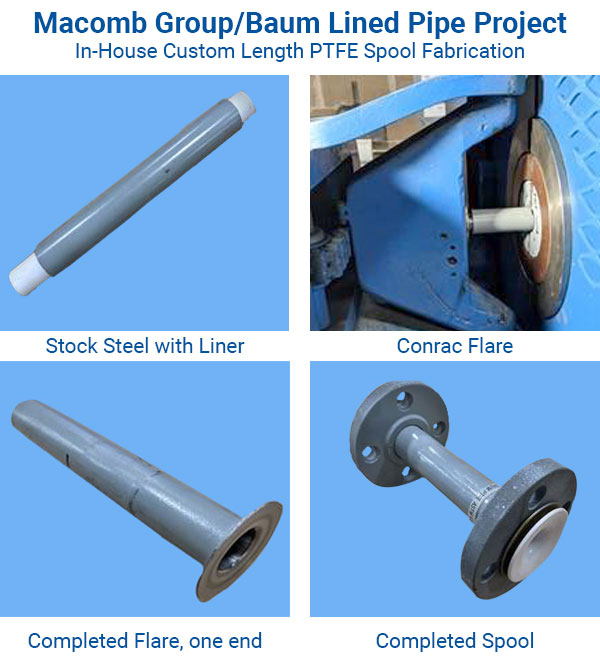

Lined pipe fabrication involves the use of a steel flaring machine referred to as a Conrac. Essentially this takes straight steel pipe and pushes the ends outward to create a steel flange face on both ends. Through a separate process the plastic liner is introduced into the steel stock and heated. It is then similarly flared to cover the steel flange faces on both ends, locking the liner into place. A finishing process allows for required quality checks and testing as well as the addition of any customer specific requests.

“Then it’s ready to go to the job site,” Henegar adds.

Henegar explains that applications for lined pipe center around environments where chemical resistance is critical. “You will usually see this type of material where chemical and temperature reactions would adversely affect standard carbon steel piping”.

Here is a look at the types of lined pipe and most common uses:

PTFE (polytetrafluoroethylene) is the most common liner and the typical choice for acidic applications, where lines may be steam cleaned, and/or systems operated at high temperatures.

PVDF (polyvinylidene fluoride) is also used in acidic applications, frequently in wet chlorine and chlorine dioxide. Pickling lines which are typically HCL are also lined with PVDF material.

Polypropylene is most often seen in utilities whether it be in water treatment facilities or scrubber systems in power plants.

The most common applications for lined pipe include:

• Urethane and foam manufacturing

• Fertilizer production

• Manufacturers of detergents/soaps/solvents

• Paint/plating facilities

• Corn-ethanol production

• Specialty chemical manufacturing

• Sugar and citrus processing

“Our current groups of customers vary from agriscience to chemical processing, steel manufacturing, and other manufacturing companies across the Midwest,” Henegar added.

It should also be noted that a significant amount of testing and approvals go into each specific application to ensure quality and effectiveness for such critical applications.

Henegar knows the importance of focusing on product and service expertise.

“As with all our specialty divisions,” he said, “we are providing the customer with technical expertise, focusing on specific product or on a particular manufacturers’ brand, and we’re making that service and expertise accessible to all Macomb Group locations and their customers.”

The addition of the new lined pipe fabrication center enhances the overall depth of product and service offered by The Macomb Group. For more information contact linedpipe@macombgroup.com